DK Shears

Harmonic Treatment

Harmonic Treatment

Couldn't load pickup availability

After 25 years of using heat to temper steel, I learned that heat only tempers the outer third of the steel. This is why the sharpening of an edge doesn’t last as long with each sharpening.

I discovered a new way of tempering the steel all to its core, thus improving its edge by 300%. This method is the harmonic treatment and it is an innovative, patented metal treatment that uses sound waves to reach the steel's core.

The microscopic fissures, gaps and cracks hidden in the surface of the steel causes the steel to underperform and wear at a faster rate. This harmonic treatment removes such defects, enhancing a shears performance and extending its life span by that 300%.

This steel treatment not only increases the life span of a shear; it also improves the cutting action by 2/3. Using more cutting surface means sharper and easier cutting and means a longer-lasting edges.

Types of tools that would benefit from the harmonic treatment include, but are not limited to:

- beautician shears,

- surgical instruments,

- cutting inserts,

- end mills,

- dies,

- drill bits,

- Taps

- and saw blades.

If a tool has to be re-sharpened or reground, then it’s a perfect candidate for the harmonic treatment

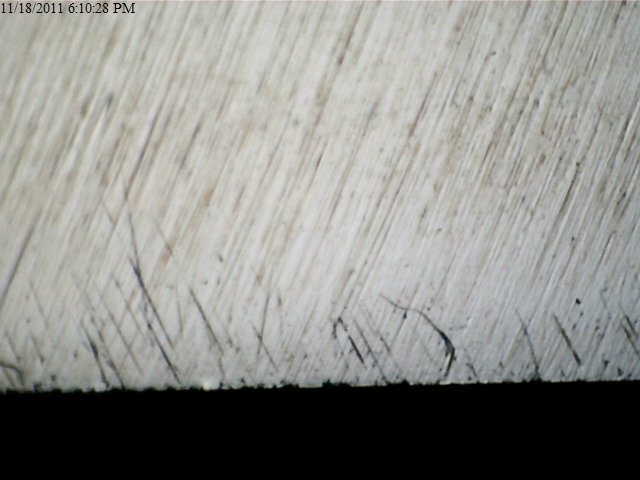

The edge of before the harmonic treatment, magnified 100,000 times. You can see the jagged edge of the sharpened blade.[/caption]

The edge of before the harmonic treatment, magnified 100,000 times. You can see the jagged edge of the sharpened blade.[/caption]

![image[1]](https://dkindustries.files.wordpress.com/2016/01/image1.jpeg) The same edge after the harmonic treatment, magnified 100,000 times again. This edge is smooth and has a straight line.[/caption]For more information about the harmonic treatment.

The same edge after the harmonic treatment, magnified 100,000 times again. This edge is smooth and has a straight line.[/caption]For more information about the harmonic treatment.